Imagnethi yeNeodymium iqiniswe ngengubo yokukhusela

Iimagnethi zeNeodymium ziphawuleka ngamandla azo akhethekileyo kunye noluhlu olubanzi lwezicelo. Zenziwe ngokudityaniswa kwe-neodymium, intsimbi, kunye ne-boron, ezi magnethi zaziwa njengezona magnethi zinamandla zisisigxina ezikhoyo namhlanje. Nangona kunjalo, ezi magnethi zifuna iingubo ezikhuselayo okanye i-plating ukuqinisekisa ubomi obude kunye nokusebenza kakuhle kwiindawo ezahlukeneyo zokusingqongileyo.

Ukwambathisa yinkqubo ebalulekileyo kwinkqubo yokuvelisa imagnethi ye-neodymium. Lo maleko ukhuselayo ukhusela umazibuthe ekudlekeni, kwimpembelelo, kunye nezinye iindlela zomonakalo ezinokunciphisa kwangethuba umazibuthe. Ngaphandle kokutyabeka okufanelekileyo, iimagnethi ze-neodymium zichaphazeleka ngakumbi kwi-oxidation, umhlwa, kunye nokunxiba ngokwasemzimbeni.

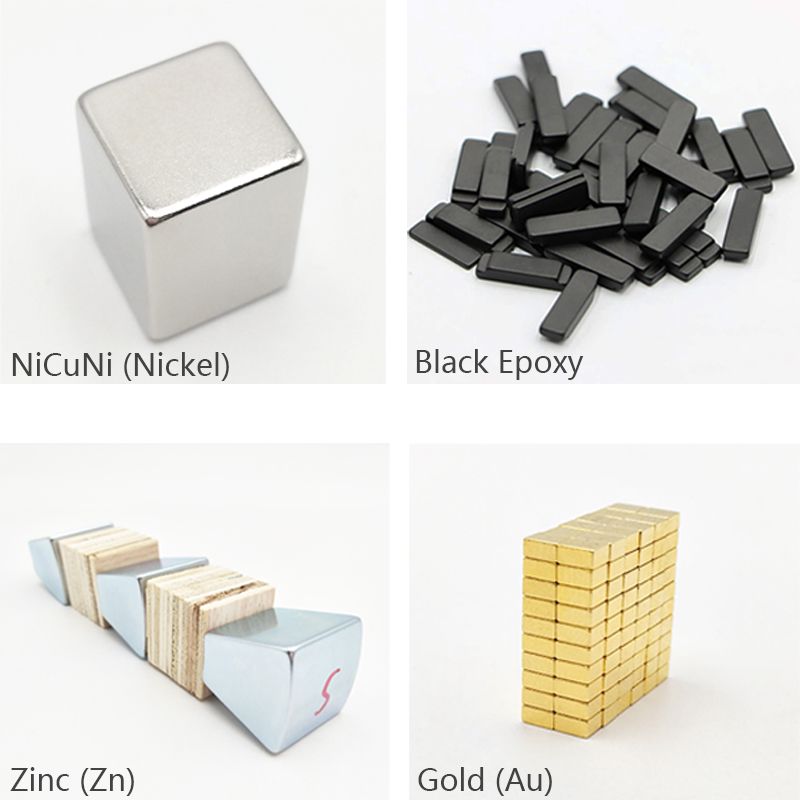

Enye yezona zinto ziqhelekileyo zokugquma iimagnethi ze-neodymium yii-nickel plating. Inkqubo ibandakanya i-electroplating umaleko obhityileyo we-nickel kumphezulu wemagnethi, ebonelela ngomqobo olungileyo ngokuchasene nokuhlwa. I-Nickel plating ayintle kuphela, kodwa yongeza umaleko owongezelelweyo wokukhusela kwizinto ezisingqongileyo ezifana nokufuma kunye nokufuma.

Enye i-coating esetyenziswa ngokubanzi yi-epoxy.Epoxy ukutyabeka lukhetho oludumileyo kuba lunamatheliso agqwesileyo kwaye luyakwazi ukumelana neekhemikhali ezininzi. Olu gqumo lwepolymer lusebenza njengomaleko olukhuselayo, lukhusela imagnethi kumswakama, impembelelo, kunye nokunxiba. I-epoxy ikwabonelela ngokugquma ukusuka kwi-conductivity yombane, iyenze ilungele izicelo ezifuna ukugqunywa kombane.

Kwezinye izicelo ezikhethekileyo, iimagnethi ze-neodymium zinokufuna iindlela ezongezelelweyo zokugquma. Umzekelo,ukugalela (Utyatyazo lwezinc) ikhethwa kwiindawo ezihlala elwandle ngenxa yokumelana kwayo nomhlwa. Ukongeza, igolide okanye isilivere yeplating ingasetyenziselwa iinjongo zokuhombisa okanye zobuhle.

Inkqubo yokwaleka ibandakanya amanyathelo amaninzi okuqinisekisa ukhuseleko olusebenzayo kunye nokubambelela. Okokuqala, umazibuthe we-neodymium ucocwa ngokucokisekileyo kwaye wohliwe ukuze kususwe nakuphi na ukungcola okunokuthi kuthintele ukubamba ukubamba. Emva koko, umazibuthe ucwiliselwe okanye utshizwe kwizinto zokwaleka ezikhethiweyo. Baye banyangelwe kwiqondo lokushisa elibangela ukuba i-coating ibe lukhuni kwaye ibambelele ngokuqinileyo kwindawo yemagnethi.

Ukongeza ekwandiseni ukuqina kwemagnethi, ukugquma kukwanceda ukuthintela umazibuthe ekuqhawukeni okanye ekuqhekekeni ngexesha lokusetyenziswa. Uluhlu oluncinci olukhuselayo lunciphisa umngcipheko wokulimala onokuthi kwenzeke ngenxa yempembelelo okanye ukuphathwa kakubi. Ukongeza, ukugquma kwenza umazibuthe ube lula ukuyiphatha njengoko ibonelela ngomphezulu ogudileyo kwaye isusa umngcipheko wokutshiza okanye ukuxobula.

Xa ukhetha i-coating yemagnethi ye-neodymium, kubalulekile ukuqwalasela iimfuno ezithile zokusingqongileyo kunye nesicelo. Izinto ezifana nobushushu, ukufuma, ukuvezwa kweekhemikhali, kunye nokukhethwa kobuhle kufuneka kuthathelwe ingqalelo. Ukongezelela, umntu kufuneka aqinisekise ukuba i-coating ekhethiweyo ayichaphazeli amandla ombane okanye ezinye izinto ezifunwayo zemagnethi ye-neodymium.

Ukuqukumbela, ukugquma kweemagnethi ze-neodymium kudlala indima ebalulekileyo ekuphuculeni ukusebenza kwazo kunye nobomi obude. Ngokufaka i-coating ekhuselayo efana ne-nickel plating okanye i-epoxy, ezi magnethi zinokukhuselwa kwi-corrosion, impembelelo, kunye nezinye iindlela zomonakalo. Ukwaleka akuphuculi nje ukuqina kwemagnethi kodwa ikwanceda ukuphucula ubuhle bayo kunye nokufaneleka koluhlu olubanzi lwezicelo. Njengoko imfuno yemagnethi ye-neodymium iqhubeka nokukhula, uphuhliso lwetekhnoloji yokwambathisa ethembekileyo neyintshayo ihlala ibalulekile ekusebenzeni kwabo ngokupheleleyo kumashishini ahlukeneyo.

Ixesha lokuposa: Oct-27-2023