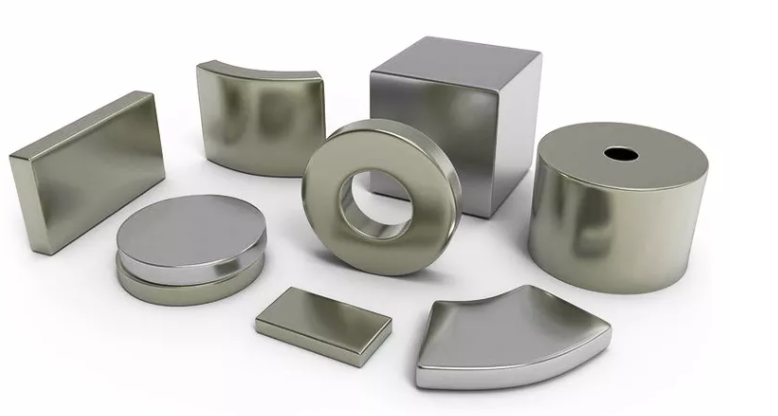

1. Iimagnethi ze-neodymium zihlala zenziwe kwi-alloy engumgubo we-neodymium, i-iron, kunye ne-boron ethi ifakwe kunye phantsi kobushushu obuphezulu kunye noxinzelelo ukwenza imveliso egqityiweyo.

2. Umxube we powder ufakwe kwi-mold okanye isitya kwaye ushushu kwiqondo lokushisa eliphakamileyo ukuze liqale ukunyibilika kunye ne-fuse.

3. Emva kokuba impahla ifikelele kwindawo yokunyibilika kwayo, ibanjwe ngeli qondo lokushisa ixesha elide de liqiniswe libe yinto enye ngaphandle kwezithuba okanye iingqungquthela phakathi kwamaqhekeza.

4. Emva kokuba uqina lwenzekile, umazibuthe unokwenziwa kwimilo kunye nobukhulu obufunwayo usebenzisa izixhobo zokusika ezahlukahlukeneyo ezifana noomatshini bokugaya okanye iileyile ngokuxhomekeka kwiinkcukacha zesicelo.

5. Imiphetho yemagnethi inokugudiswa ukuba iyanqweneleka phambi kokuba igqunywe ngesigqubuthelo esikhuselayo esinje nge-nickel okanye i-zinc ngeenjongo zokuxhathisa umhlwa.

Iinkcukacha ezithe kratya, nceda ubone itshati engezantsi:

| Hayi. | Inkqubo Flow | Inyathelo leMveliso | Ukusebenza kweTekhnoloji |

| 1 | Ukuhlolwa kwezinto ezikrwada | 1.ICP-2.chemical Analysis-3.Analyser(C&S) | Ukufunyanwa kweRohs Uvavanyo lokubumba Uhlalutyo Lobunyulu |

| 2 | Material ekrwada Pre-unyango | 4.Sawing- 5. Ukomisa- 6.Impact Cleaning | Sawing Iron Ukomisa Umoya Oshushu Ukucocwa kweMpembelelo |

| 3 | Ulawulo lwezithako | 7.Ulawulo lwezithako | Ukulinganisa ubunzima Xuba izinto ezikrwada |

| 4 | I-Strip Casting | 8.Vacuumizing-9.Melting-10.Casting | Ukutshayela Ukunyibilika Ukunyibilika Iyaphosa |

| 5 | Ukuncipha kweHydrojeni | 11.Ngaphambi kokunyanga-12.Vacuumizing-13.Yongeza iHydrogen | Ukunyanga kwangaphambili Ukutshayela Ukudilizwa ngeHydrogen |

| 6 | Ukugaya | 14.Ukuqhekeka-15.Ukugaya-16.Jet Mill-17.Granularity Control | Ukuqhekeka Ukusila IJet Mill Umlinganiselo oqhelekileyo |

| 7 | Ukucinezela | 18. Ubungakanani bepowder -19.Pre-pressing - 20.Pressing -21.Ukucinezela isostatic | Ubunzima bomgubo Ukucofa kwangaphambili Ukucinezela Ukucinezela isostatic |

| 8 | Sintering | 22.Vacuumizing- 23.Sintering -24 Unyango lobushushu | Ukutshayela Sintering Unyango lobushushu |

| 9 | Ukuhlolwa | 25.BH igophe-26.I-PCT-27.Uvavanyo loxinaniso -28.Roughcast Ukuhlolwa | Umlinganiselo wemagnethi Uvavanyo lwe-coefficient yobushushu PCT Umlinganiselo woxinaniso Ukuhlolwa |

| 10 | Umatshini | 29.Ukugaya -30.Ucingo lokusika-31.I-blade yangaphakathi yokusika | Ukusila Ukusika ucingo Ukusika i-blade yangaphakathi |

| 11 | Uvavanyo lwesampula ye-QC | Uvavanyo lwesampula ye-32.QC | Uvavanyo lwesampula ye-QC |

| 12 | Chamfering | 33.Ukuhlekisa | Chamfering |

| 13 | Electroplating | 34.Electroplating Zn 35. Electroplating NICUNI 36.Phosphating 37. Chemical Ni | I-Electroplating Zn Electroplating NICUNI Phosphating okanye Chemical Ni |

| 14 | Ukuhlolwa kweCoating | 38.Ukutyeba-39.I-Corrosion Resistance -40.Ukubambelela-41.-UkuHlolwa kokunyamezela | Ukutyeba Ukunyangwa kokuMhlwa Ukuncamathela UkuHlolwa kokunyamezela |

| 15 | Imagnethi | 42.Uhlolo oluGqibeleleyo- 43.Ukumakishwa- 44.Ukulungisa/Ukuguquka- 45.Ukwenza imagnethi | Gqibezela uHlolo Ukumakisha Ukucwangcisa / ukuguqukela Ukwenza imagnethi Uvavanyo lweMagnetic Fiux |

| 16 | Ukupakisha | 46. I-Magnetic Flux- 47.Bagging- 48. Ukupakisha | Bagging Ukupakisha |

Ixesha lokuposa: Feb-15-2023